What’s ideal about IDEEL?

21-06-2023

Why our IDEEL connector is the ideal connector for IEMs and other headphones!

Let's face it - cables are the weak link for headphones. Especially IEMs. They get wound up, pulled on, bent, and abused. Yeah, wireless is an option - but Bluetooth still leaves a lot on the table when it comes to audio quality. So we do wired, and we expect the connectors to break and die.

Now, the typical approach is to use MMCX or 2 pin type connectors for your IEMs. They're small, and they're fairly ubiquitous (even though there's about 4 styles of each type). So why did we go with what we did?

It was pretty simple, actually. Let's start with what a connector is supposed to do. It's supposed to provide an electrical connection between two devices - in this case, your amplifier/phone/dongle and the left or right IEM. That's it. It's not going to make you rich (it'll more likely make you poor!), it's not going to whiten your teeth or solve male pattern baldness. It's just going to make two electrical connections.

A small majority of IEMs today use an MMCX connector. Why? Because someone, 10 years ago, thought it was a good idea. And we've paid for it ever since! You see, MMCX are really small, and have two connections, and are coaxial (so they're easy to plug - no particular alignment needed). But they're not designed for the use that headphones demand. Check this out:

Here's the spec for a widely-used MMCX vendor, one of the largest in the world. Lots of stuff there, right? Where there's three parameters we really care about:

- Total Insertion/Extraction Force

- Salt Spray

- Mating Durability

So what do these 3 mean, and why do we care? Well, let's start with total insertion/extraction force. This is the amount of force you need to apply to connect/disconnect the connector. And we see it's 6 to 15 Newtons. How much is a Newton (not a fig one)? One Newton is about 102 grams, or about 0.22 pounds. So it takes between 600 and 1500 grams (or 1.2 to 3 pounds) of force to make the connection. That's a LOT of force on a small connector, that's on a very small product! Ouch! And it takes a LOT of force to disconnect as well. Meaning your earbuds are going to get ripped out of your ears when the cable is yanked on. Guaranteed. That's a ton of force over and over on a small, delicate connector.

What about salt spray? It's rated for 5% solution, for 48 hours! Hey, 5% sounds like a lot, given that ocean water is only 3.5% salt content! But here's the point - human sweat is around 10% salt content. Meaning that your MMCX connector is rated for just 24 hours of exposure to human sweat. Ouch. I hope you're not using them when you exercise. Or are walking around outside in summer on Las Vegas!

The third problem? Mating durability. It's rated for 100 cycles total. Meaning you can attach/detach the cable 100 times before you start to compromise the connections. Now, you might not pop the cable on and off so many times - and that's fine. You might not sweat much, either! But plenty of people pop cables on and off to roll cables, clean parts, store the cables, etc. So you have a limited number of those cycles.

Is it any wonder that MMCX connectors die so regularly?

So what's the Periodic solution?

Glad you asked! We wanted something that was low insertion force, rated for thousands and thousands of insertions, lots of large contact area for salt resistance - with thick gold plating to make it a small issue to start with. Well, we chose to use what pretty much EVERY wired headphone uses: a TRS (or TS) connector. You know, the phono jack. Like the 3.5mm on the other end of the cable. It's rugged, rated for thousands of connections, and easy to align.

We went with the 2.5mm TS (Tip Sleeve - TRS is Tip Ring Sleeve) connector for our IEMs. It's the same as used in the Sennheiser HD700, lots of Hifiman over ears, and many, many more headphones. Because it's reliable, intuitive, and ubiquitous. Well, maybe not ubiquitous on IEMs, right? RIGHT! See, the problem is that while a 2.5mm TS plug is small, the 2.5mm TS jacks are BIG. Like 6-7mm diameter, 25mm long, and more. Plenty small to fit into an overear headphone but WAY to big to fit in an IEM.

So, we solved that with - IDEEL:

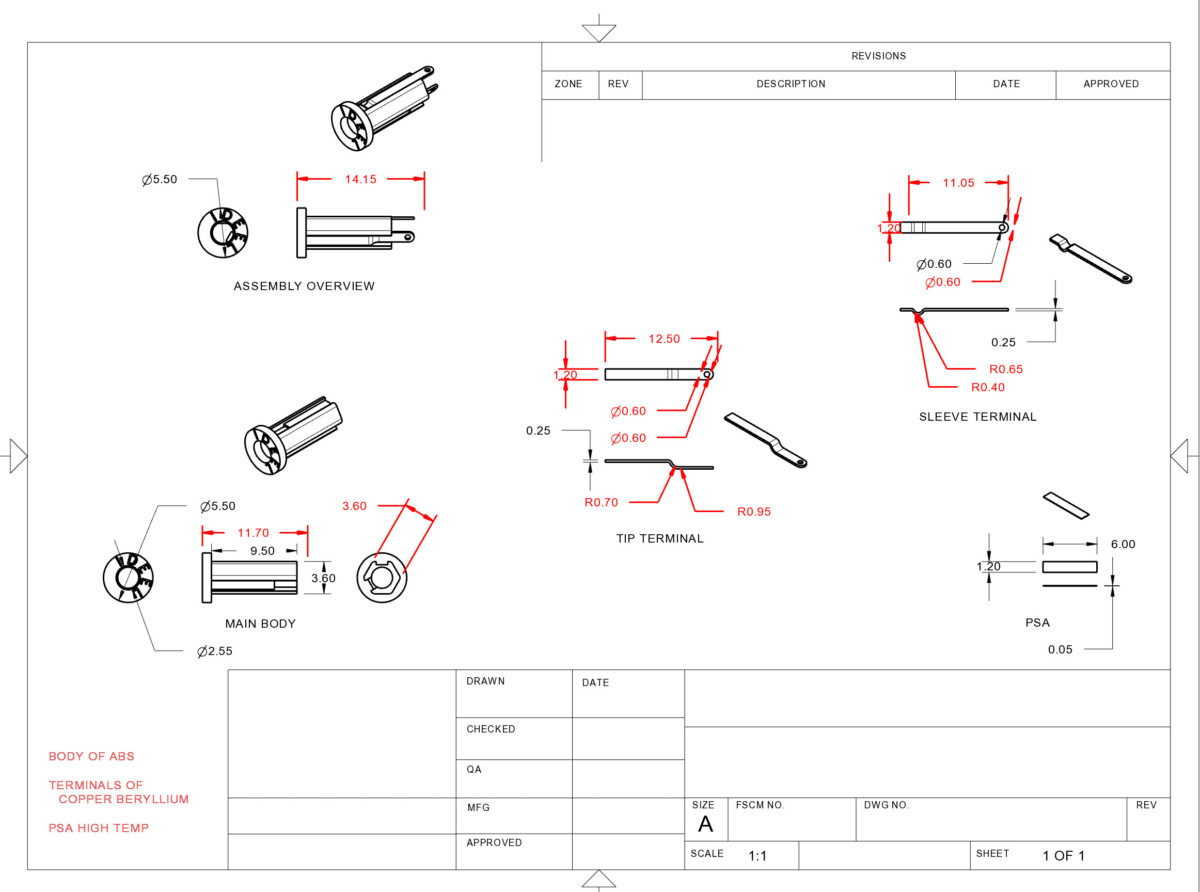

IDEEL stands for IEM Direct Electrical Engagement Link. It's a fully-compliant 2.5mm TS jack. But shrunk down to fit into IEMs. How small? Well, the outer round flange is just 5.5mm in diameter (smaller than many cables). The hexagonal main body (hex shaped so it doesn't rotate in the IEM) is just 3.6mm across. And the length is tiny - literally the same length as the 2.5mm plug portion - 10.5mm long! We use copper beryllium contacts for the top and bottom, bonded on with high-strength permanent pressure sensitive adhesive - and they are also held in-place by the receiving hole in the IEM itself. A small hole at the top is for the wire to the speaker.

The result? We have a TS plug/jack system that's rated for literally tens of thousands of insertions, not 100. Can handle 10% salt spray for 300 hours. And it's easy to use, because it only takes 1 to 3 Newtons of force to use, so it's delicate. And it means your IEMs won't get yanked out of your ears, too!

So that was our solution - make our own jack. Yeah, it's different - but better. It's the right thing to do. And it makes a better product overall. Custom cables are easier to build with the 2.5mm TS rather than the MMCX. And it's low cost! In fact, if a manufacturer wanted to use our IDEEL connector, they can - for free! We'll put them directly in touch with the connector factory and they can buy, royalty free. We're not looking to become billionaires at $0.03 a shot on jacks...

So there you have it. Why the IDEEL jack is ideal. And why you deserve better than an MMCX for your IEMs.